Painting and decoration of glass containers

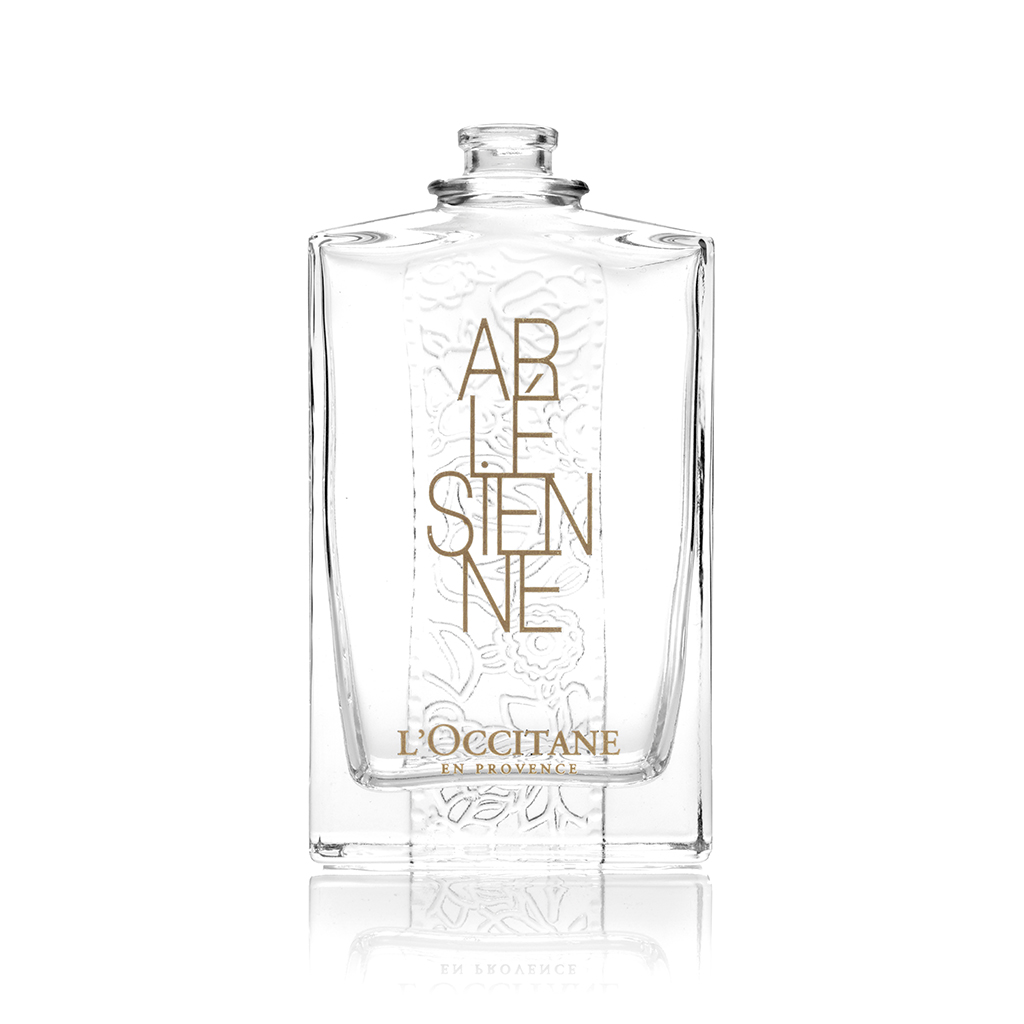

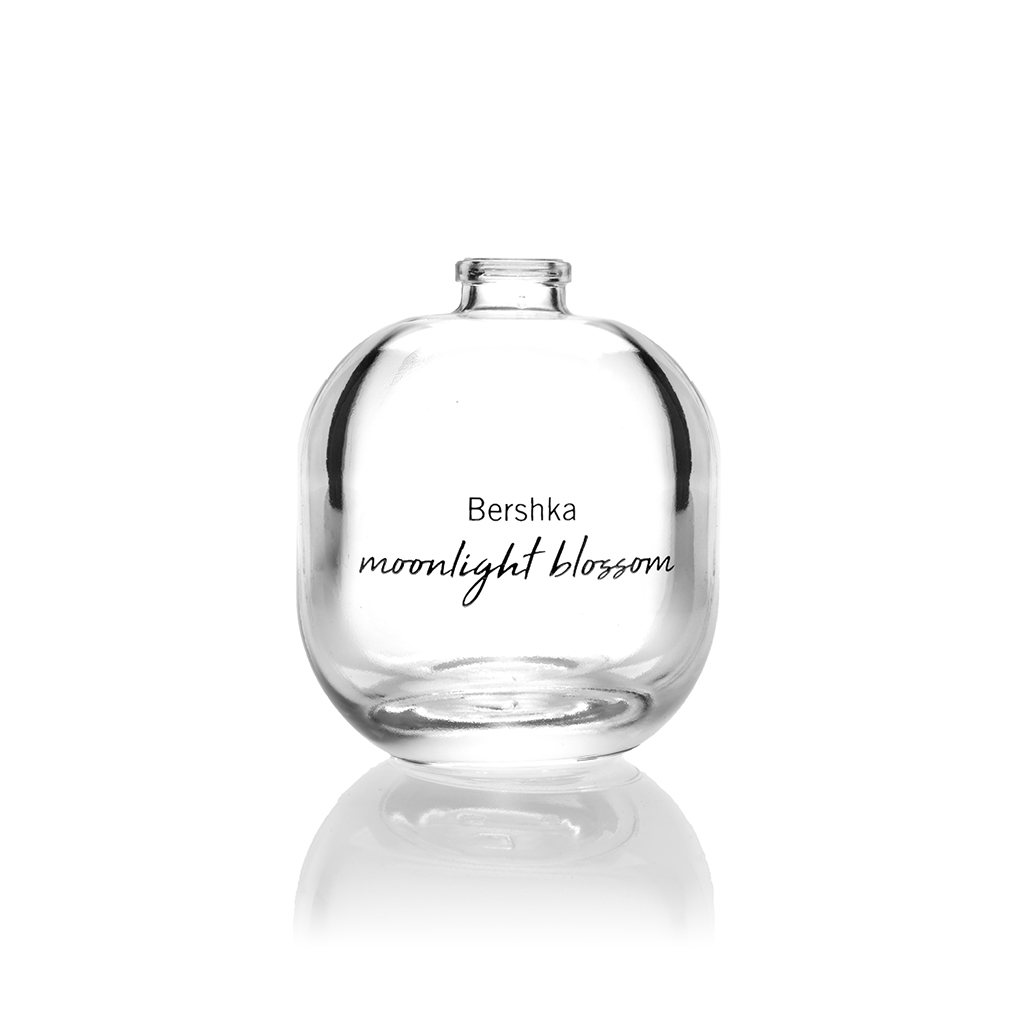

At Ramon Clemente, not only do we manufacture glass containers, but we also paint and decorate them. This way, we achieve unique, cutting-edge designs for our customers worldwide.

Our company currently has 3 facilities:

1/ Ramon Clemente (El Masnou/Barcelona), where we manufacture glass containers.

2/ Walter Friedrich (La Llagosta/Barcelona), where we paint and metallise the glass containers.

3/ Walter DEC (L’Hospitalet / Barcelona), where we decorate the finished product.

Painting our glass containers

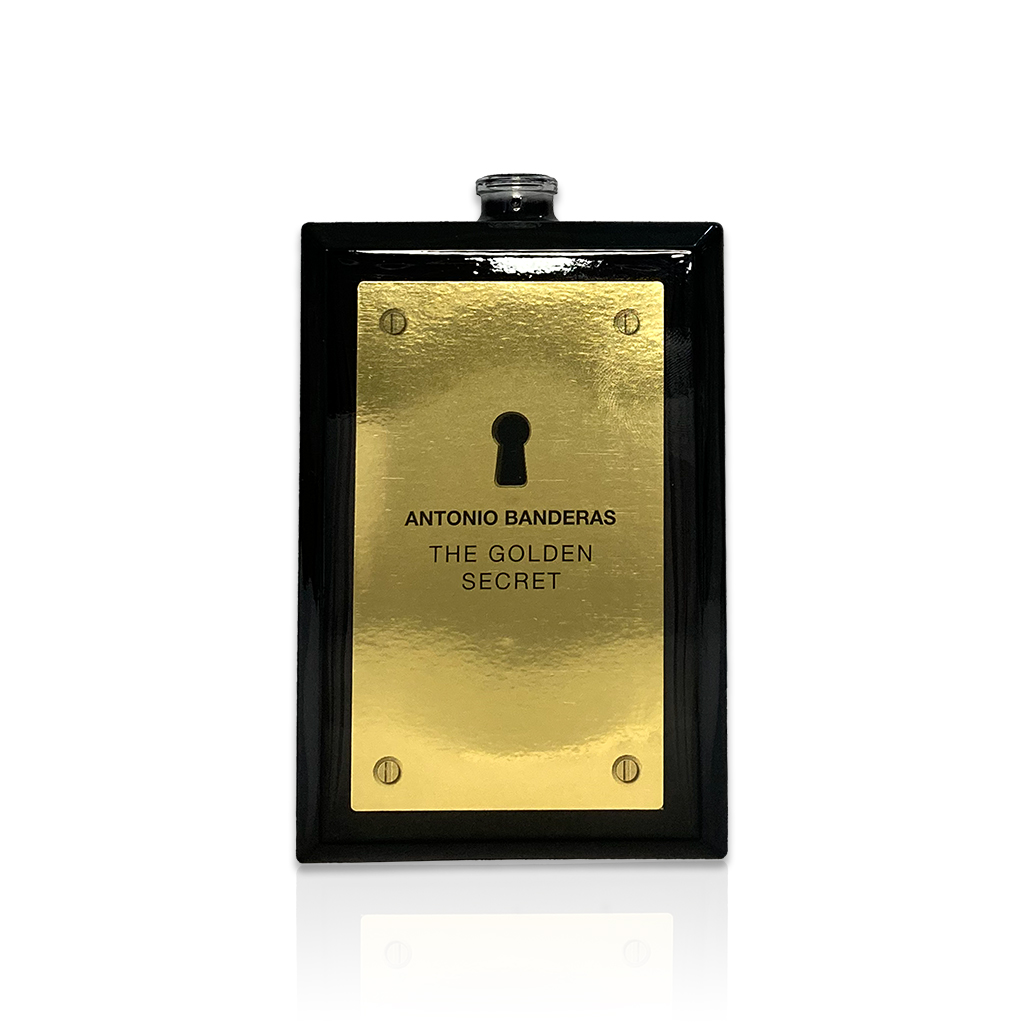

At our Walter Friedrich facilities, we paint and metallise glass containers for perfumery and cosmetics, and jewellery items, among others. At Walter Friedrich, we paint over 50,000 glass bottles every day.

We work with top-quality materials and have a high environmental sensitivity since we only use water-based varnishes and eco-friendly paint.

We have a wide variety of options for our customers’ glass containers, from porcelain-like finishes and translucent effects to matte or gradient finishes.

Perfume glass bottle with a 1, 2 or 3-colour gradient.

Glass bottle with an opaque glossy effect.

Glass bottle with a porcelain effect.

Glass bottle with a translucent effect.

Glass bottle with a soft touch effect.

Glass bottle with a matte effect.

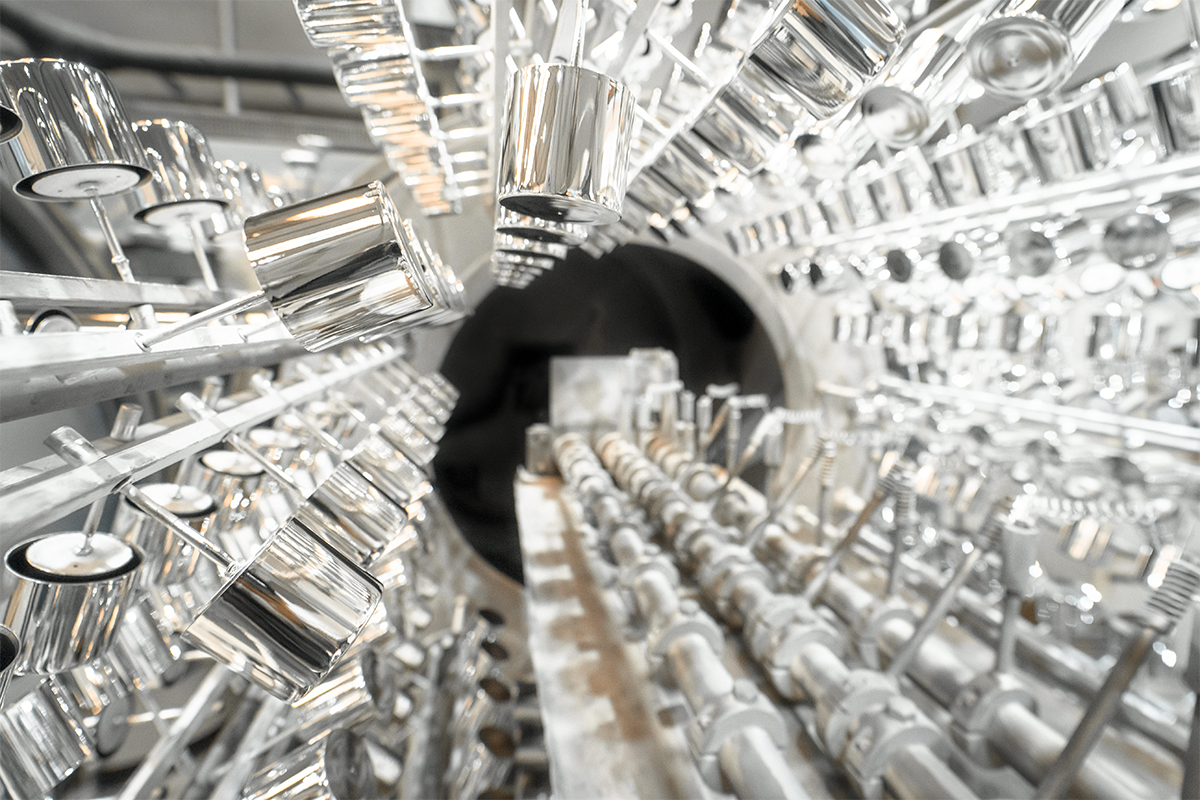

Metallising glass containers – high vacuum metallisation

What is high vacuum metallisation?

We use the high vacuum metallisation technique among our painting and decoration methods to give all types of materials a thin metallic coating. The items coated using the high vacuum technique can be made of wood, plastic or other metals/materials.

Pros of high vacuum metallisation

It is a technique that can be used to metallise lids, caps, and glass bottles used in the perfumery, decoration, cosmetics or gourmet food industries, to name a few. It is a highly innovative method that gives the customer many more options when it comes to choosing materials to work with.

The high vacuum metallisation technique is the technique our customers request the most.

Thanks to this method, the customer can offer a much more exclusive appearance and give the selected items a longer useful life. It also leads to cost savings as the metallic coating can be applied to lower-cost items that will have a perfect finish.

Piezas realizadas por metalización por alto vacío

Items coated using high vacuum metallisation

High-vacuum metallisation applied to jewellery items

High vacuum metallisation applied to different perfumery items

Metallic colours applied using high vacuum metallisation

Decoration of glass bottles and containers

Besides glass bottle manufacturing, painting and metallising, we also decorate our customers’ glass bottles.

A wide range of techniques (screen printing, hot stamping, and thermoplastic gold and platinum pastes) help us offer the most exclusive and state-of-the-art decorations.

Below we describe each one of the decoration techniques we can offer at Ramon Clemente.

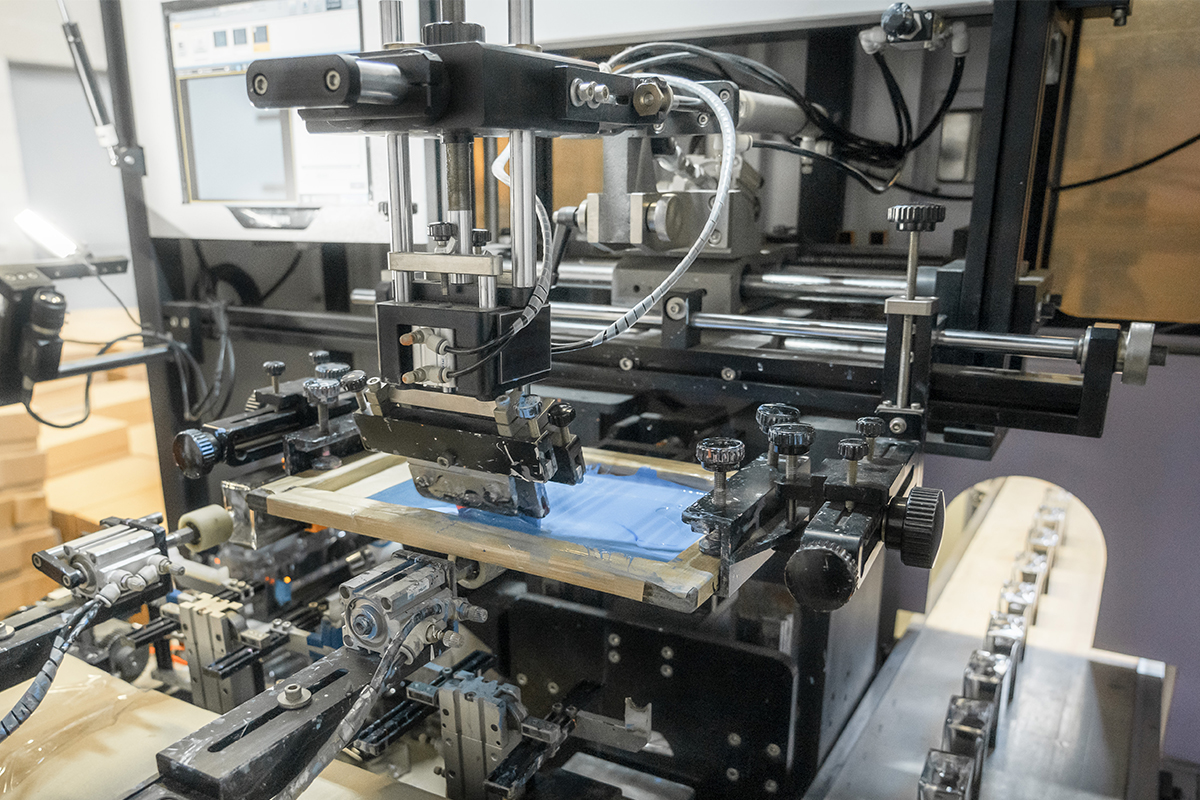

Screen printing

The screen printing of glass containers is a printing technique used to produce texts, logos and images on any type of bottle. It consists of transferring ink through a fabric mesh.

We have the latest generation of screen printing machinery. It uses an eco-friendly screen printing technology with a low carbon footprint in all productions since the ink vitrification ovens are electric.

In screen printing, we control the thickness of the ink layer through the diameter of the fibres in the mesh. Thanks to this, we can apply thicker and thinner ink layers.

We use cutting-edge inks and printing techniques that allow for a customised service with the highest quality finishes, always respecting the environment.

Hot-Stamping

Hot stamping is a printing technique applied using heat transfer. This technique gives a premium, glossy finish and is quite versatile since the entire range of Pantone® colours is available.

Vitrification

Vitrification is a printing technique that preserves the actual screen printing until the container is destroyed. It requires the use of vitrification furnaces, which reach 600 °C. In recent years, these furnaces have undergone a technological change to make them environmentally friendly. Now, they are electric furnaces designed to be energy efficient.

Labelling

Thanks to the flexibility of our automatic flat labelling machine, we offer a labelling service that can adjust to the dimensions of each container. This saves time and handling costs, and our customers receive a completely finished product.

Glueing

We have manual glueing lines that allow us to provide an end-to-end service to our customers.

Ultraviolet and organic inks

We can customise all types of containers, meeting our customers’ needs to the maximum extent. Our ink laboratory can create inks that are incredibly close to the requested Pantone® colours.

We give our customers comprehensive advice on everything from the manufacture to the decoration of their glass containers

Manufacturing and selling painted and decorated glass containers, making them as original as possible for our customers and using the latest innovations is not a mere selling transaction. It is, in fact, an opportunity to understand, from the very begging, the ideas that our customers want their product to reflect. This means that we design, produce, paint, and decorate the product together, giving our customers a complete service throughout the entire process. It truly is a comprehensive service that turns ideas and designs into a reality.

Our company carries out this comprehensive and joint process, from the design of the glass container and the adaptation using standard glass bottles to the creation of a completely customised and unique bottle – our exclusives. To do so, we use state‑of‑the‑art manufacturing, painting and decorating techniques.

We make your ideas come true. Tell us about yours!